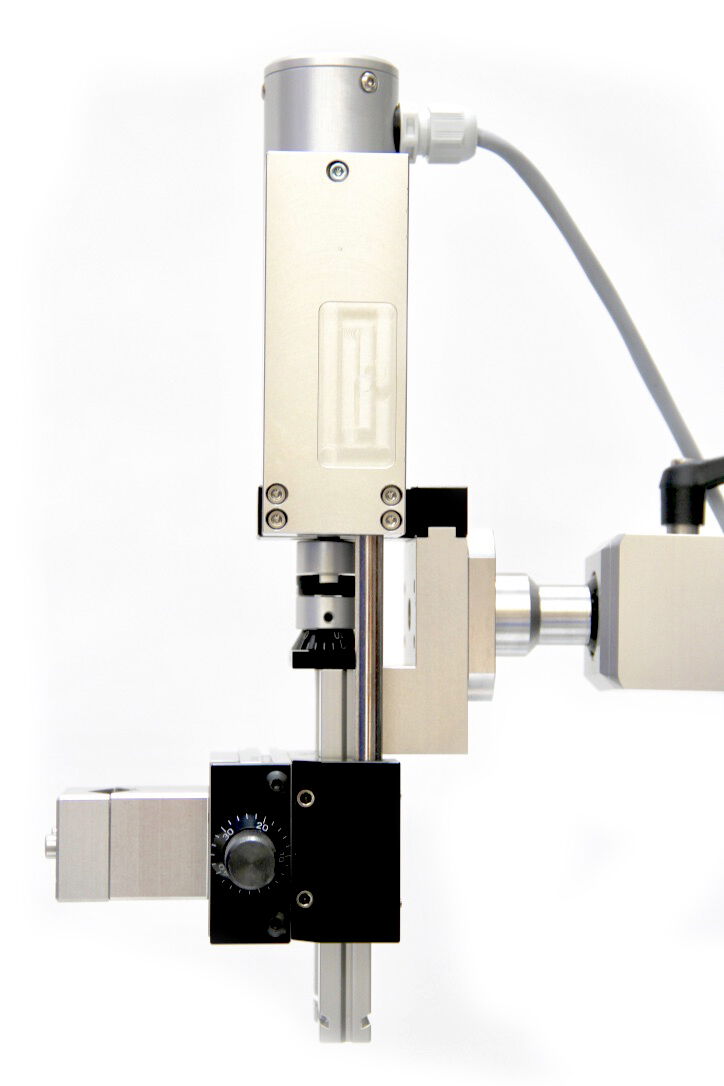

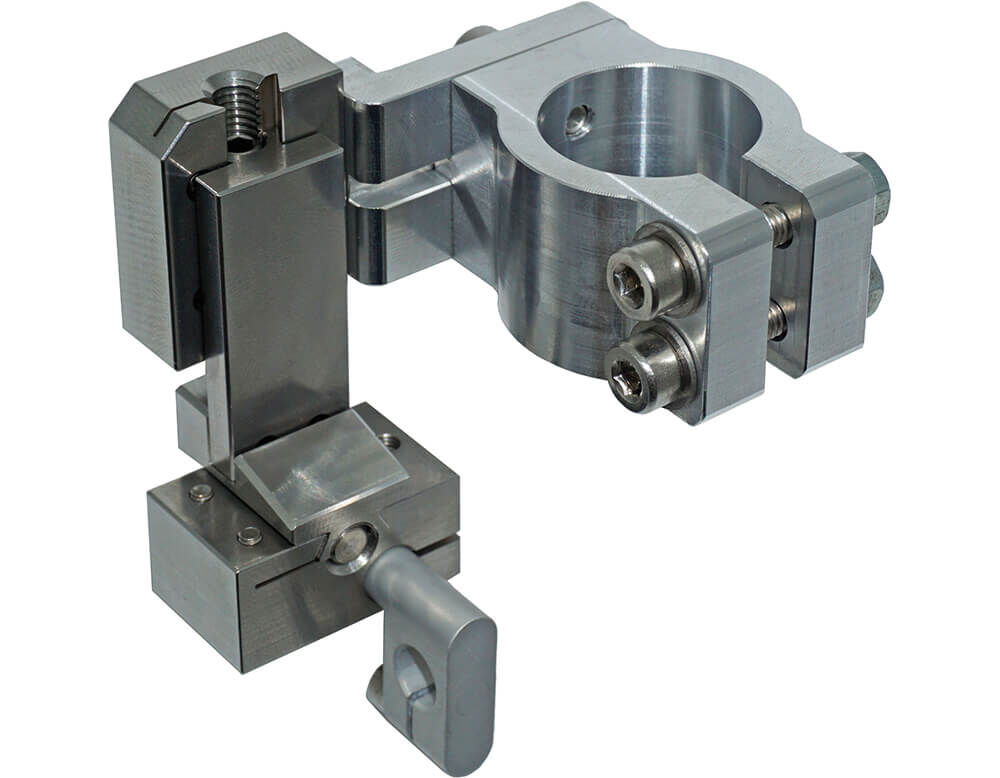

Incl. AVC motor with limit switching and 8 m connection cable, slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

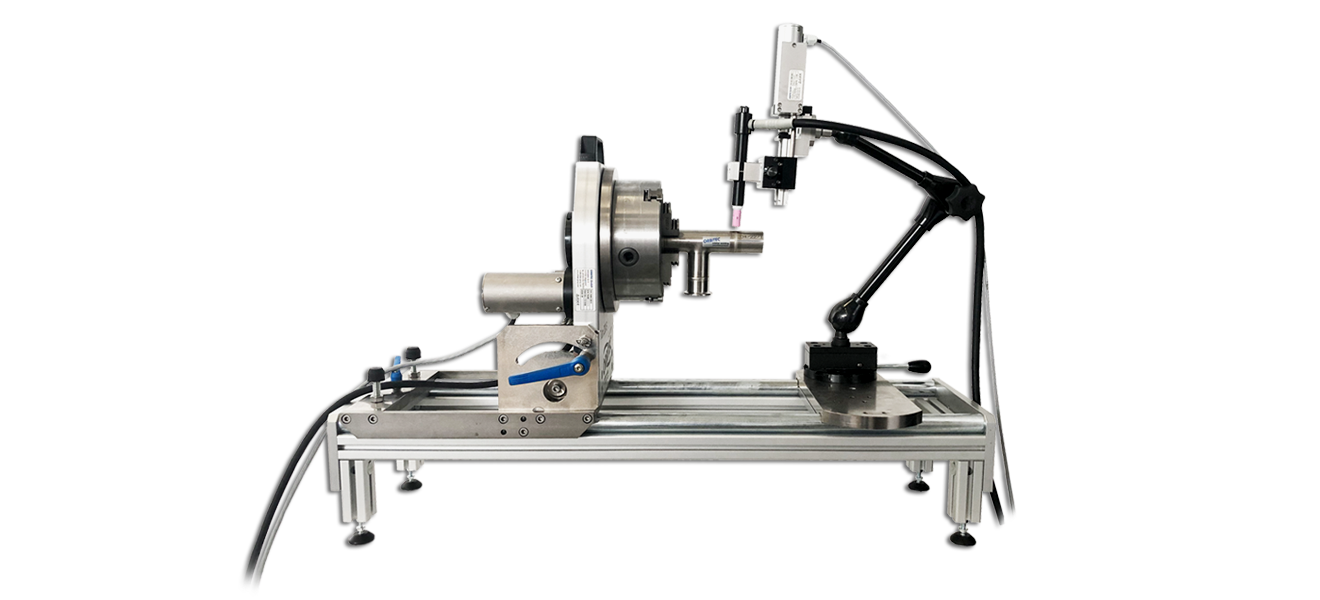

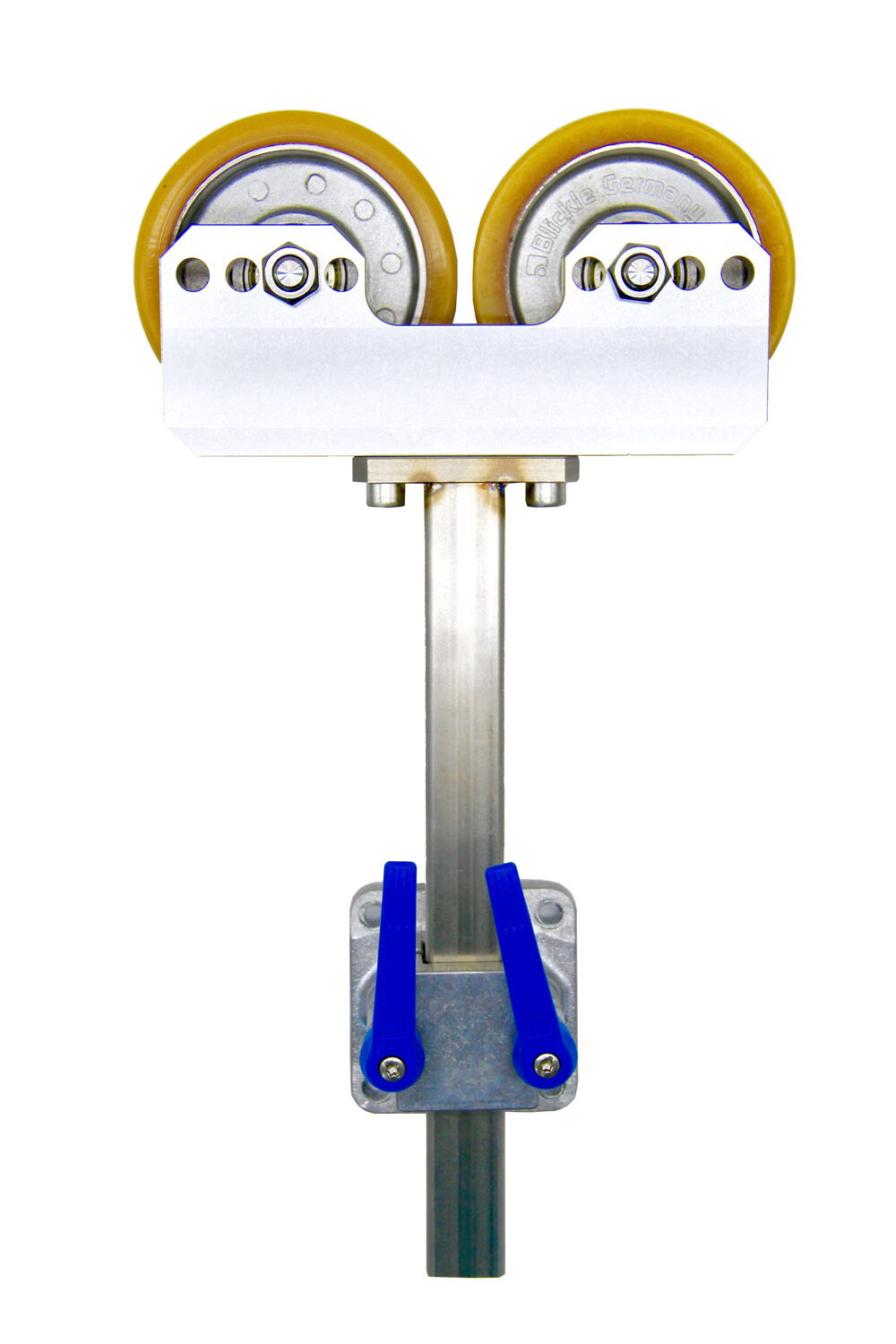

Our turntable system provides options for the welding of non-standard components (which cannot be clamped in a standard head). The welding process is different from the weld heads and tongs, due to the rotation of the clamped component around the torch. A hydraulic articulated arm is used for the correct alignment of the TIG torch with regards to the component. The device has a hollow shaft for the formation of the inner component along the centre axis. The Orbitec turntable system is easy to handle because of its customized design.

Welding of non-standard components

Processing of high volumes

Alternative clever solution, customised, robust

Turn table, especially suitable for orbital components with higher quantities and can be connected to all Orbitec controllers.

Scope of application:

Tube size range: OD 10 – 230 mm | 0.393 – 9.055″

Max. load in horizontal position: 50 kg

Technical Data:

Chuck: Three-jaw chuck with axis adjustment

Swivel range: 0 – 90° stepless

Power transmission: max. 300 A

Weight: 88 kg

Dimensions (L x W x H): 1.020 x 360 x 750 mm

Item number

1.2.1858

Turn table

Three-jaw chuck

Interchangeable jaws

Chuck key

Robust articulated arm with central mechanical clamping

Ground cable

Interconnection cable with wire and AVC outlet

Pneumatic torch adjustment

Pneumatic centring and clamping

Pneumatic tailstock

Special diameters up to 1.000 mm

Special lengths and complete workstation equipment available on request

Special torch consumables

Special lengths and versions with a higher ED available on request.

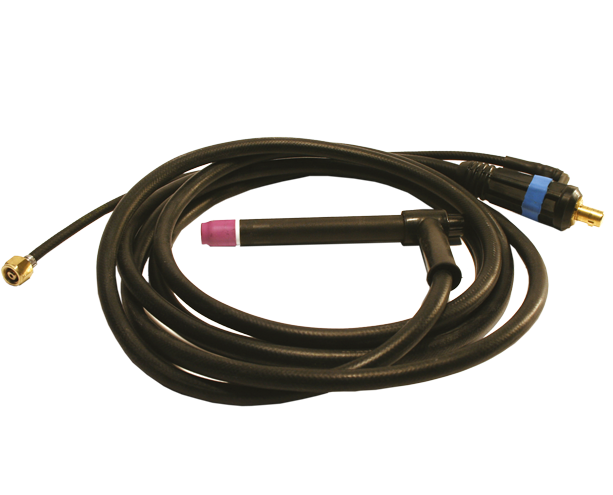

Gas-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm ED: AC: 105 A, DC:150 A, 60% (10 min.)

Item number 1.2.1814

Water-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm ED: AC: 160 A, DC: 220 A, 100% (10 min.)

Item number 1.2.1815

Slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp

OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

Item number

1.2.1861

Incl. AVC motor with limit switching and 8 m connection cable, slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

Item number

1.2.1859

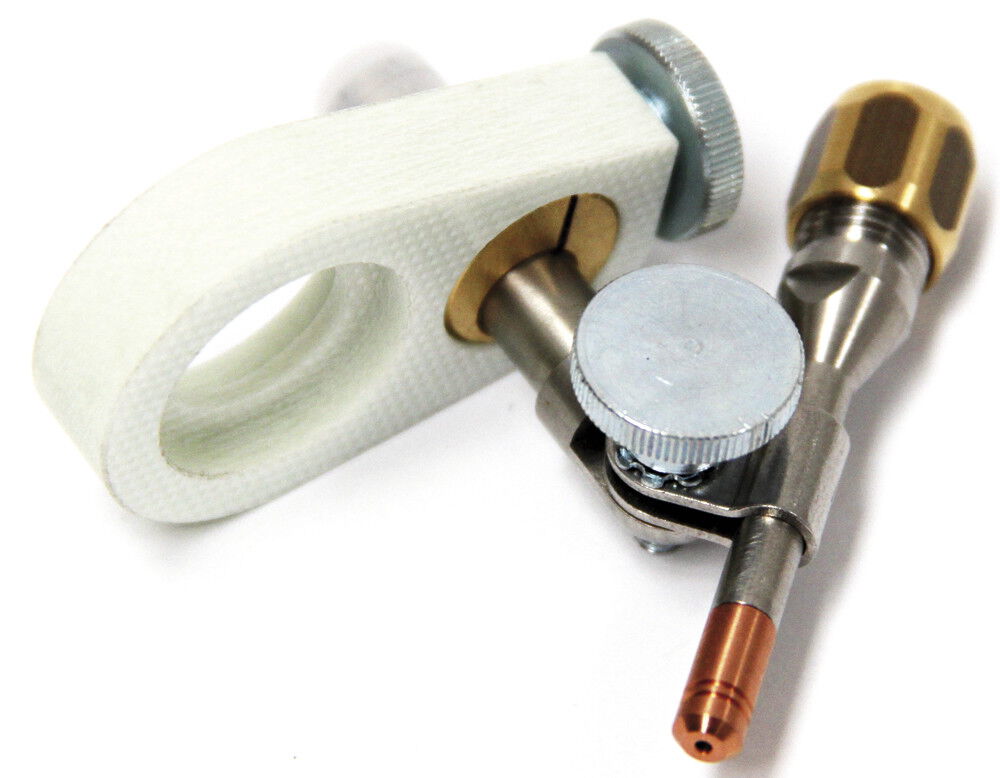

Incl. wire outlet nozzle and three nozzle tips for 0.8 / 1.0 / 1.2 mm

Item number

1.2.1852

(3D adjustable via linear unit)

Item number

1.2.1869

Item number

1.2.1860

Orbitec design, manufacture and supply a comprehensive range of systems, products and accessories for the Orbital TIG Process. Our products are employed across a diverse range of industries including: Pharmaceutical, Biotechnology, Chemical, Food & Dairy, Semiconductor, Aerospace, Petrochemical, Offshore and Nuclear.